How AquaRing® works

See how AquaRing® products work in a few steps described below. Download the data sheet.

System Elements

System Elements

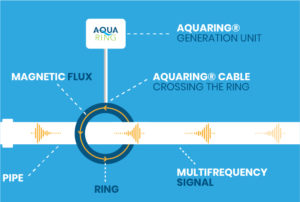

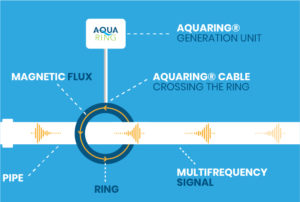

AquaRing® consists of a signal generation electronical unit, cable connection and a ferrite ring for installation around the pipe.

Unlike other products, AquaRing® is extremely easy to install and minimal space is required for installation because there is no inconvenient connection between the ring and the device.

Signal induction

Signal induction

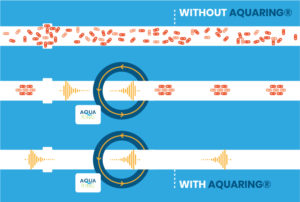

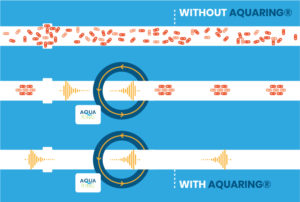

AquaRing® emits complex multi-frequency signals on water distribution pipes (AquaRing® patent pending signals). This process follows the transformer principle: the pipes, with the ring and the water in them, represent the secondary coil.

Piping distribution

Piping distribution

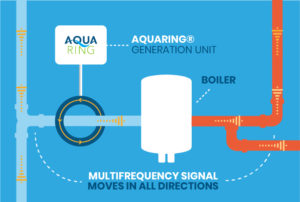

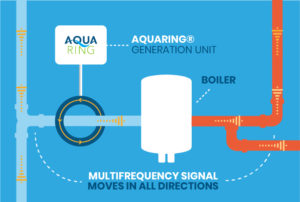

AquaRing® signal propagates into pipes and water system equipment, in both axial directions of the pipe.

Pipes can be made of plastic or metal and does not require sectioning or any adaption of the plumbing system as the water is an electrical conductor.

Certificate

Certificate

All AquaRing® devices are CE marked and comply with IEC 61010-1 standards.

The signal generated to the water distribution pipes is a low power type and is isolated from the power supply of AquaRing® unit. It is absolutely harmless to people and other equipment or systems.

How AquaRing® works

See how AquaRing® products work in a few steps described below. Download the data sheet.

AquaRing® consists of a signal generation electronical unit, cable connection and a ferrite ring for installation around the pipe.

Unlike other products, AquaRing® is extremely easy to install and minimal space is required for installation because there is no inconvenient connection between the ring and the device.

AquaRing® emits complex multi-frequency signals on water distribution pipes (AquaRing® patent pending signals). This process follows the transformer principle: the pipes, with the ring and the water in them, represent the secondary coil.

AquaRing® emits complex multi-frequency signals on water distribution pipes (AquaRing® patent pending signals). This process follows the transformer principle: the pipes, with the ring and the water in them, represent the secondary coil.

All AquaRing® devices are CE marked and comply with IEC 61010-1 standards.

The signal generated to the water distribution pipes is a low power type and is isolated from the power supply of AquaRing® unit. It is absolutely harmless to people and other equipment or systems.

How it removes limescale

See how AquaRing® products work in a few steps described below. Download the data sheet.

The water property of retaining dissolved materials in solution is defined by a specific chemical equilibrium formula. Under certain variations, such as raising in temperature, the equilibrium shifts and limescale formation takes place.

Its crystallization requires starting points, such as the surface roughness of the pipes, where a continuous process of deposit settlement begins.

The water property of retaining dissolved materials in solution is defined by a specific chemical equilibrium formula. Under certain variations, such as raising in temperature, the equilibrium shifts and limescale formation takes place.

Its crystallization requires starting points, such as the surface roughness of the pipes, where a continuous process of deposit settlement begins.

After the precipitation process, the released carbon dioxide attacks the already stratified limescale. This process is facilitated by the mechanical forces of the electric field of AquaRing®, that acts on deposited limescale molecules and promotes their disintegration.

The installation of AquaRing® transforms the natural process of accretion of limescale into a process of progressive dissolution.

How it removes Bacteria and Viruses

See how AquaRing® products work in a few steps described below. Download the data sheet.

The presence of micro-organisms in water plants is a serious problem for human and animal health (see Legionella cases). The current practices are expensive periodic thermal or chemical treatments, which, not only makes the plant temporarily unavailable but can also damage it. AquaRing®, on the contrary, works continuously without any periodic costs, ensuring the availability of the hydraulic plants and enhancing their functionality during the years.

Bacterial contamination can lead to bio-fouling, very harmful in hydraulic systems, causing obstructions in pipes, valves and heat exchangers, generating corrosion phenomena and reducing the efficiency of heat exchange of components. Due to its antibacterial properties, AquaRing® prevents the formation of bio-fouling and related corrosions.

In recent years scientific evidence has confirmed the bactericidal efficacy of limited-size electric fields, if applied for a substantial amount of time.

AquaRing® effectively breaks down bacteria even when organized in resistant biofilms by permanently distributing the induced electric field in the water contained in the hydraulic system.

By removing the calcareous stratifications, AquaRing® eliminates the nutrition and the support material provided the colonies of bacteria structured in biofilms, rendering them exposed to the electric field.

Unlike other anti-bacterial products, the effect of AquaRing® is not limited to the point of application, but is effective throughout the plant and even where there is no waterflow.

How to protect against corrosion

See how AquaRing® products work in a few steps described below. Download the data sheet.

The corrosion of metal pipes can be due to galvanic currents or water with low salt content, but in any case itis crucial for the exchange of free electrons from metal to water.

For the Skin Effect, the signal caused by AquaRing® on the metal pipes leads to electrical currents only on their outer surface. AquaRing® defends against the corrosive processes mentioned above by draining free electrons from the inner surface of pipes to the outer surface.

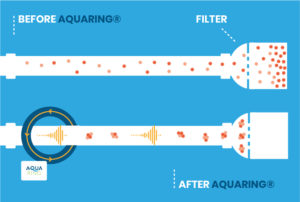

For many plants, the maintenance of filters is greatly important and they must be periodically replaced or cleaned. AquaRing® orients and aggregates the particles in suspension, creating larger agglomerations that penetrate to a lesser extent inside the filter.

This results in significant savings, lowering the frequency of replacement, and extends the life of filter washing, and also improves the filtering capacity of smaller particles.

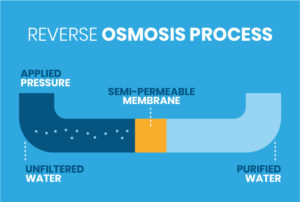

In osmosis processes, the membrane tends to degrade due to the presence of limescale, bacteria and algae, which also involve a progressive occlusion with further mechanical stress and increased consumption.

AquaRing® removes limescale, bacteria and aggregating particles by flocculation. It also reduces the occlusion of the membrane, the osmotic pressure and the relative energy consumption, allowing a smaller number of backwashes.

How it removes limescale

See how AquaRing® products work in a few steps described below. Download the data sheet.

Formation of limescale

Formation of limescale

The water property of retaining dissolved materials in solution is defined by a specific chemical equilibrium formula. Under certain variations, such as raising in temperature, the equilibrium shifts and limescale formation takes place.

Its crystallization requires starting points, such as the surface roughness of the pipes, where a continuous process of deposit settlement begins.

Prevention of limescale

Prevention of limescale

AquaRing® creates an electric field in the water that manages to form in clusters of calcium and carbonate ions. These clusters form directly into the flow, creating innumerable starting points preferable to the superficial roughness of pipes and to already present calcareous layers.

The limescale, instead of settling, remains in suspension and then can be discharged from the flow.

Limescale Removal

After the precipitation process, the released carbon dioxide attacks the already stratified limescale. This process is facilitated by the mechanical forces of the electric field of AquaRing®, that acts on deposited limescale molecules and promotes their disintegration.

The installation of AquaRing® transforms the natural process of accretion of limescale into a process of progressive dissolution.

How it removes Bacteria and Viruses

See how AquaRing® products work in a few steps described below. Download the data sheet.

Health impact

Health impact

The presence of micro-organisms in water plants is a serious problem for human and animal health (see Legionella cases). The current practices are expensive periodic thermal or chemical treatments, which, not only makes the plant temporarily unavailable but can also damage it. AquaRing®, on the contrary, works continuously without any periodic costs, ensuring the availability of the hydraulic plants and enhancing their functionality during the years.

Bio-fouling

Bio-fouling

Bacterial contamination can lead to bio-fouling, very harmful in hydraulic systems, causing obstructions in pipes, valves and heat exchangers, generating corrosion phenomena and reducing the efficiency of heat exchange of components. Due to its antibacterial properties, AquaRing® prevents the formation of bio-fouling and related corrosions.

Bacteria Prevent

Bacteria Prevent

In recent years scientific evidence has confirmed the bactericidal efficacy of limited-size electric fields, if applied for a substantial amount of time.

AquaRing® effectively breaks down bacteria even when organized in resistant biofilms by permanently distributing the induced electric field in the water contained in the hydraulic system.

Bacteria Elimination

By removing the calcareous stratifications, AquaRing® eliminates the nutrition and the support material provided the colonies of bacteria structured in biofilms, rendering them exposed to the electric field.

Unlike other anti-bacterial products, the effect of AquaRing® is not limited to the point of application, but is effective throughout the plant and even where there is no waterflow.

How to protect against corrosion

See how AquaRing® products work in a few steps described below. Download the data sheet.

Protection against corrosion

The corrosion of metal pipes can be due to galvanic currents or water with low salt content, but in any case itis crucial for the exchange of free electrons from metal to water.

For the Skin Effect, the signal caused by AquaRing® on the metal pipes leads to electrical currents only on their outer surface. AquaRing® defends against the corrosive processes mentioned above by draining free electrons from the inner surface of pipes to the outer surface.

Flocculation

For many plants, the maintenance of filters is greatly important and they must be periodically replaced or cleaned. AquaRing® orients and aggregates the particles in suspension, creating larger agglomerations that penetrate to a lesser extent inside the filter.

This results in significant savings, lowering the frequency of replacement, and extends the life of filter washing, and also improves the filtering capacity of smaller particles.

Reverse osmosis

In osmosis processes, the membrane tends to degrade due to the presence of limescale, bacteria and algae, which also involve a progressive occlusion with further mechanical stress and increased consumption.

AquaRing® removes limescale, bacteria and aggregating particles by flocculation. It also reduces the occlusion of the membrane, the osmotic pressure and the relative energy consumption, allowing a smaller number of backwashes.